Perfect Your Solution

of Air Compressor

for Laser Cutting Industry

The laser cutting industry must use protective gas when processing. Of course, the air is a simple and economical protective gas. The function of the air compressor for laser cutting machine is to compress a part of the compressed air with high-purity oxygen and high-purity nitrogen to provide the cutting gas for the cutting head.

As a power source, it is supplied to the cylinder of the clamping table, and a part of it is used to purge and remove the dust of the optical path system. Therefore, the special air compressor for laser cutting is indispensable for every laser cutting equipment.

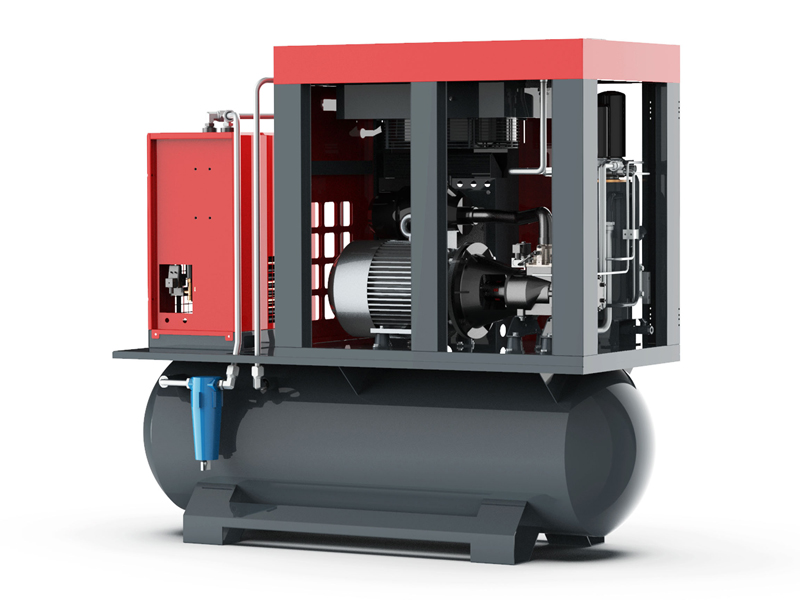

Screw Air Compressor

♦ Motor

Adopt high-efficiency and energy-saving IE4 motor

♦ Air End

New 20CrMrTi (alloy steel) two-stage rotor material, 5:6 tooth rotor profile, higher strength, and better energy efficiency. The new bearing structure, using copper bearings greatly improves the service life of

the machine body

♦ Oil And Gas Tanks

The oil and gas separation tank is designed with an external oil separation core for easy maintenance

♦ Oil Separator

The oil separation core adopts the MAN brand, and the oil and gas separation effect is better

Refrigerated Air Dryers

High-quality compressed air for your equipment and processes

The aluminum plate-fin series of refrigerated dryers ensures dry compressed air, prolongs the service life of your equipment, and ensures excellent production quality. Efficient water removal prevents corrosion in the compressed air network and in the air tools. All in all, it reduces your maintenance costs and improves your overall level of production with complete peace of mind.

♦ Excellent performance

Excellent performance

High-efficiency plate-fin heat exchanger

Low relative humidity of outlet air

Professional water removal function

Dew point 2-10°C

♦ Energy saving and carbon reduction

Energy saving and carbon reduction

50% reduction in energy consumption

compared to shell and tube dryers

Optimized refrigeration system

Precision Filter

This precision filter has obtained the national patent, is qualified through pressure and precision and various indicators, and strictly implements the compressed air quality standard: ISO8573

This series of products has a unique appearance, realizes the exquisite design of every detail in and clever and convenient parallel way, and under the premise of meeting the laser industry 3.0Mpa pressure requirements, with gain years in compressed air processing and compressed air quality requirements and continuous innovation and technical precipitation, thus has the absolute ability to provide solutions for the vast number of users in the compressor air system industry, to ensure the long-term stable operation of laser cutting, laboratory, medicine, food, electronics, chemical, and other precision filtration

Compliant with ISO 8573 Standard

Test compressed air quality according to lSO 8573

♦ Residual oil measurement – OlL-Check 400

Continuously and accurately measure the residual oil content in the form of steam from 0.001 mg/m³ to 2.5 mg/m³. Class 1 compressed air quality can be through a low detection limit of 0.001mg/m³ (ISO 8573)

♦ Particle counter PC 400

The high-precision optical particle counter PC 400 can measure particles as low as 0. 1 um in size, so it is suitable for monitoring the quality of compressed air at level 1 (ISO 8573).

♦ Residual humidity – dew point sensor FA 510

FA 510 can measure the pressure dew point up to – 80℃td. At this time, continuous measurement can also ensure that the alarm will be triggered immediately whether the compressed air dryer fails

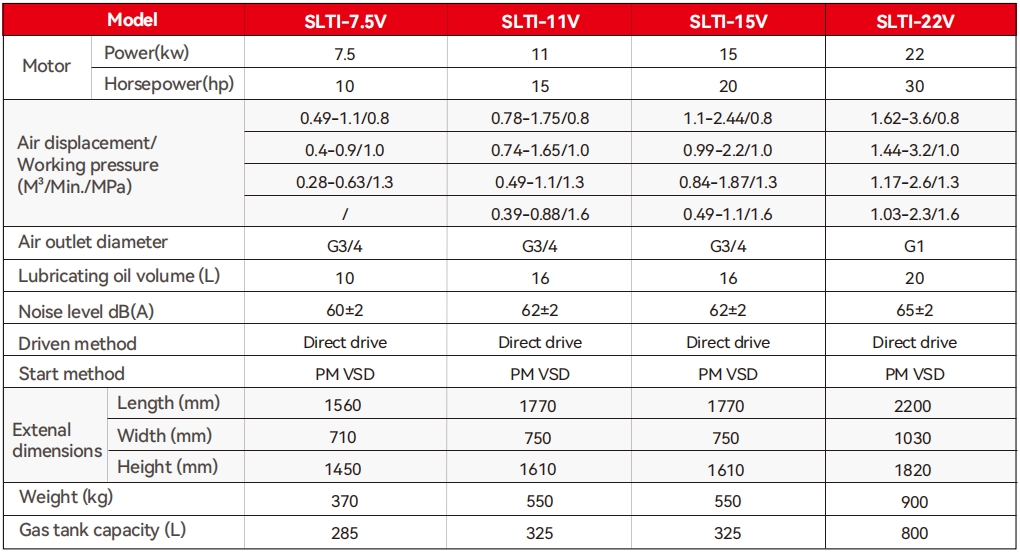

Technical Parameters

Keep us Update on Latest Air Compressor Newsletter

Enhancing Fiber Laser Cutting with Advanced Screw Air Compressors

In the modern manufacturing landscape, precision and efficiency have become paramount considerations for industries that rely on cutting-edge technologies to shape materials with exceptional accuracy. Fiber laser cutting, a technology that utilizes high-energy laser beams to cut through various materials, has gained prominence due to its ability to achieve intricate cuts with minimal heat-affected zones. The demand for precise and efficient cutting solutions has underscored the need to optimize every aspect of the fiber laser cutting process.

Amid the pursuit of precision, it’s essential to recognize the often-overlooked yet critical role that compressed air plays in fiber laser cutting machines. Compressed air serves as a versatile utility, assisting in various aspects of the process, such as cooling the laser head, clearing debris from the cutting area, and even enhancing the cut quality by preventing oxidation. This multifaceted role positions compressed air as a vital component in maintaining the overall efficiency and performance of fiber laser cutting machines.

As industries continue to refine their processes for optimal results, the focus turns to the quality and reliability of the tools at hand. In this context, the integration of advanced screw air compressors emerges as a significant advancement in enhancing fiber laser cutting.

These compressors, known for their efficiency, reliability, and versatility, have the potential to elevate the capabilities of fiber laser cutting machines by providing consistent and high-quality compressed air. This article delves into the transformative impact of using advanced screw air compressors to enhance the precision, efficiency, and overall performance of fiber laser cutting processes.

Understanding Fiber Laser Cutting

Fiber laser cutting technology has revolutionized precision cutting across industries. It involves focusing a high-intensity laser beam onto a material’s surface, causing rapid heating and localized melting or vaporization. The focused energy creates a narrow, precise cut, resulting in minimal material distortion and heat-affected zones. This technology is widely used for applications ranging from automotive manufacturing and aerospace to electronics and medical devices.

In the context of fiber laser cutting, compressed air serves multiple crucial purposes. It aids in the removal of molten material and debris from the cutting area, preventing unwanted residues that could compromise the quality of the cut. Compressed air also assists in cooling the laser head, preventing overheating during the cutting process. To achieve optimal cutting quality and precision, it’s imperative to have a consistent and high-quality air supply that is free from contaminants and fluctuations.

While the role of compressed air in fiber laser cutting is essential, maintaining optimal air pressure and quality presents challenges. Traditional compressor systems might struggle to deliver the consistent air pressure required for uninterrupted cutting. Additionally, factors such as moisture content, oil particles, and contaminants in the compressed air can adversely affect the quality of the cut and the overall performance of the cutting machine. Addressing these challenges is crucial for achieving reliable and high-quality fiber laser cutting outcomes.

The Significance of Air Compressors

Air compressors play a pivotal role in the fiber laser cutting process by supplying the necessary compressed air to various components of the cutting machine. The quality of this compressed air directly impacts the performance and precision of the cutting process.

Advanced screw air compressors are designed to deliver clean, dry, and high-quality compressed air. By effectively removing moisture, oil, and contaminants from the air, these compressors ensure that the air supplied to the cutting machine is free from impurities that could compromise cutting quality and equipment longevity.

The quality of compressed air has a direct correlation with the overall cutting performance. Impurities present in the compressed air can lead to inconsistent and unpredictable cutting results. Moisture can cause oxidation and affect material integrity, while oil particles can deposit on surfaces and create imperfections.

Inaccurate cuts, reduced efficiency, and increased material wastage are potential consequences of poor compressed air quality. Advanced screw air compressors contribute to consistent cutting performance by delivering air that meets the stringent requirements of fiber laser cutting, ultimately enhancing the precision and efficiency of the process.Traditional compressor types, such as reciprocating and rotary vane compressors, have been widely used in various applications, including supplying compressed air to cutting machines. However, these compressor types have limitations in maintaining a stable and consistent air supply, particularly when it comes to the demands of fiber laser cutting. Fluctuations in air pressure and quality can lead to variations in cutting performance.

Additionally, traditional compressors might introduce moisture and contaminants into the air supply, which can adversely affect the cutting process. The shortcomings of traditional compressors highlight the need for more advanced solutions like screw air compressors in the context of fiber laser cutting.

Unveiling Advanced Screw Air Compressors

Screw air compressors represent a modern and efficient solution for supplying compressed air in various industrial applications. Unlike traditional compressor types, screw compressors utilize a rotary screw mechanism to compress air. This design offers several advantages, including smooth and continuous operation, reduced energy consumption, and the ability to provide a constant supply of compressed air without pulsations.

The advantages of screw compressors are particularly pronounced in the context of fiber laser cutting machines. Screw compressors are renowned for their reliability, durability, and consistent performance. Their oil-free design ensures that the compressed air remains free from oil contamination, which is crucial for maintaining the integrity of laser-cut materials.

Moreover, screw compressors operate quietly, produce less vibration, and require less maintenance compared to traditional compressor types. These benefits make screw compressors an ideal choice for supplying the high-quality and stable compressed air required by fiber laser cutting machines.

Screw compressors directly address the challenges associated with maintaining optimal air pressure and quality in fiber laser cutting. Their ability to provide a continuous and consistent supply of compressed air eliminates fluctuations in air pressure that can disrupt the cutting process. The oil-free operation of screw compressors ensures that the air supplied is devoid of oil particles and contaminants that could adversely affect cutting quality.

Additionally, the advanced design of screw compressors minimizes the risk of introducing moisture into the compressed air, a critical consideration for preventing oxidation during the cutting process. By mitigating these challenges, screw compressors contribute to a seamless and efficient fiber laser cutting experience.

In the realm of fiber laser cutting, advanced screw air compressors emerge as a game-changing solution that addresses critical requirements for stable, clean, and high-quality compressed air. Their innovative design and inherent advantages position them as key enablers in enhancing the precision, efficiency, and overall performance of fiber laser cutting machines.

Enhancing Efficiency and Precision

One of the standout features of advanced screw air compressors is their ability to provide improved air delivery to fiber laser-cutting machines. The consistent and steady airflow generated by screw compressors ensures a reliable and continuous supply of compressed air.

Unlike traditional compressors that may experience pulsations and pressure fluctuations, screw compressors deliver a smooth and uniform airflow that enhances the stability of the cutting process. This improved air delivery contributes to the overall efficiency and precision of fiber laser cutting operations.

Maintaining consistent air pressure and quality is essential for uninterrupted cutting operations. Screw compressors excel in this aspect by offering a reliable source of compressed air that meets the stringent requirements of fiber laser cutting. The absence of pressure fluctuations and the removal of contaminants and moisture from the compressed air ensure that the cutting process remains stable and predictable. Consistency in air pressure and quality translates into consistent cutting performance, resulting in higher precision and minimized material wastage.

The integration of advanced screw air compressors directly contributes to the optimization of cutting speed, accuracy, and material utilization in fiber laser cutting. The steady and consistent airflow provided by screw compressors allows for precise control over the cutting process parameters. This precision enables faster cutting speeds without compromising on accuracy, leading to higher productivity.

Additionally, the elimination of impurities in compressed air minimizes the chances of material defects, resulting in improved material utilization and reduced scrap rates. The synergy between screw compressors and fiber laser cutting technology culminates in efficient operations that yield precise and high-quality cuts.

By enhancing air delivery, ensuring consistent air pressure and quality, and optimizing cutting parameters, advanced screw air compressors play a pivotal role in elevating the efficiency and precision of fiber laser cutting.

This transformation translates into tangible benefits for industries that rely on precise cutting for their manufacturing processes, enhancing their competitiveness and enabling them to meet the demands of the modern market.

Reduced Maintenance and Downtime

- The Impact of Screw Compressor Design on Maintenance

The design of advanced screw air compressors significantly influences maintenance requirements and procedures. Unlike traditional compressors that may involve complex maintenance routines and frequent oil changes, screw compressors offer a streamlined approach.

Their oil-free design eliminates the need for oil-related maintenance tasks, such as oil changes and filter replacements. This simplicity not only reduces maintenance complexity but also minimizes the potential for errors and oversights, contributing to the overall efficiency of fiber laser cutting operations.

- Minimizing Downtime Due to Maintenance and Repairs

Downtime can have a substantial impact on productivity and profitability. Advanced screw air compressors are engineered to minimize downtime associated with maintenance and repairs. Their robust construction and fewer moving parts result in reduced wear and tear, leading to extended intervals between maintenance activities.

Additionally, the elimination of oil-related components eliminates the risk of oil-related malfunctions, reducing the likelihood of unexpected breakdowns. This reliability ensures that fiber laser cutting machines can operate consistently, minimizing disruptions to production schedules.

- Longevity and Reliability of Advanced Screw Air Compressors

The longevity and reliability of advanced screw air compressors are significant advantages in the context of fiber laser cutting operations. Their durable construction and efficient operation contribute to extended lifecycles, providing a consistent source of compressed air over an extended period. The reduced need for frequent maintenance interventions further contributes to the overall reliability of screw compressors. By choosing advanced screw air compressors, industries investing in fiber laser cutting technology can expect sustained performance and operational continuity.

The streamlined maintenance minimized downtime, and extended reliability of advanced screw air compressors result in enhanced operational efficiency for fiber laser cutting machines. The reduction in maintenance complexities and the assurance of consistent performance contribute to improved productivity, reduced operational costs, and ultimately, greater competitiveness in today’s fast-paced manufacturing landscape.

Customization for Fiber Laser Cutting

The versatility of advanced screw air compressors allows for seamless integration into various fiber laser cutting machine setups. Manufacturers understand that each cutting machine has unique specifications and requirements. To meet these specific needs, screw compressor solutions can be tailored to match the airflow demands, pressure ranges, and operational parameters of the cutting equipment. This customization ensures that the compressed air supply aligns precisely with the capabilities and demands of the fiber laser cutting process.

In the pursuit of enhanced operational efficiency, integration between screw air compressors and cutting machine controls is pivotal. Modern fiber laser cutting machines often feature advanced automation and control systems that enable precise adjustments and real-time monitoring. By seamlessly integrating screw compressor controls with the cutting machine’s interface, operators can manage both components from a unified platform. This integration streamlines operation, simplifies maintenance scheduling, and enhances the overall user experience.

Different industries and applications require tailored solutions to address their specific challenges and demands. Whether it’s automotive manufacturing, aerospace components, or intricate designs in jewelry, each cutting application comes with distinct requirements.

Advanced screw air compressor manufacturers understand the importance of adapting their technology to suit diverse needs. By collaborating closely with industries and understanding their unique requirements, manufacturers can develop customized solutions that optimize the performance and results of fiber laser cutting processes.

The customization capabilities of advanced screw air compressors empower industries to maximize the benefits of fiber laser cutting technology. By aligning compressor solutions with cutting machine specifications, integrating controls for seamless operation, and addressing unique application requirements, industries can achieve precision, efficiency, and reliability that meet the highest standards across various cutting scenarios.

Sollant Laser Cutting Machine Dedicated Screw Air Compressor

In the realm of advanced manufacturing technologies, precision and efficiency are paramount. Among these technologies, laser cutting has emerged as a pivotal method for achieving intricate and accurate cuts in various materials. Behind the success of laser cutting machines lies a critical component that often goes unnoticed but plays a pivotal role: the air compressor. In this context, Sollant stands as a distinguished name, offering specialized screw air compressors tailored for laser cutting machines.

Sollant is a professional Turkish air compressor supplier that has earned a reputation for its commitment to quality, innovation, and customer satisfaction. With a comprehensive understanding of the unique requirements of laser cutting processes, Sollant has designed a range of screw air compressors specifically optimized to enhance the performance of laser cutting machines.

Sollant’s dedication to excellence stems from its foundation in Turkish manufacturing expertise. Renowned for its thriving industrial sector, Turkey has become a hub of innovation and quality in various industries, including air compressor manufacturing. Sollant has emerged as a key player in this landscape, offering cutting-edge solutions to meet the demands of modern manufacturing.

Sollant’s specialized screw air compressors are crafted to cater to the unique demands of laser cutting machines. These compressors ensure a steady, reliable, and high-quality supply of compressed air—an essential component of laser cutting. By delivering consistent air pressure and purity, Sollant’s compressors contribute to the precision, efficiency, and overall performance of laser cutting processes.

Sollant’s screw air compressors come with a range of advantages that set them apart:

- Efficiency:

Designed with advanced rotary screw technology, these compressors ensure smooth and continuous operation, minimizing energy wastage and enhancing overall efficiency.

- Reliability:

Sollant’s compressors are built to last, featuring robust construction and minimal wear and tear. This translates to reduced maintenance requirements and extended operational lifecycles.

- Customization:

Recognizing the diversity of laser cutting applications, Sollant offers customization options to align compressor specifications with specific cutting machine requirements.

- Sustainability:

Sollant’s energy-efficient compressors contribute to lower operational costs and reduced environmental impact, aligning with modern sustainability objectives.

In the world of laser cutting, precision is non-negotiable. Sollant’s dedication to providing specialized screw air compressors for laser cutting machines cements its role as a reliable partner in achieving precision, efficiency, and excellence. As industries continue to push the boundaries of manufacturing capabilities, Sollant remains committed to supporting their endeavors with cutting-edge air compressor solutions.

Sollant’s laser cutting machine dedicated screw air compressors exemplify the synergy of innovation and expertise. With a focus on quality, reliability, and customization, Sollant equips industries with the tools to elevate their laser cutting processes to new heights of precision and efficiency. As the manufacturing landscape evolves, Sollant stands as a beacon of excellence, providing solutions that power the future of manufacturing with unwavering precision.