Rotary Screw Air Compressor Supplier in Turkey

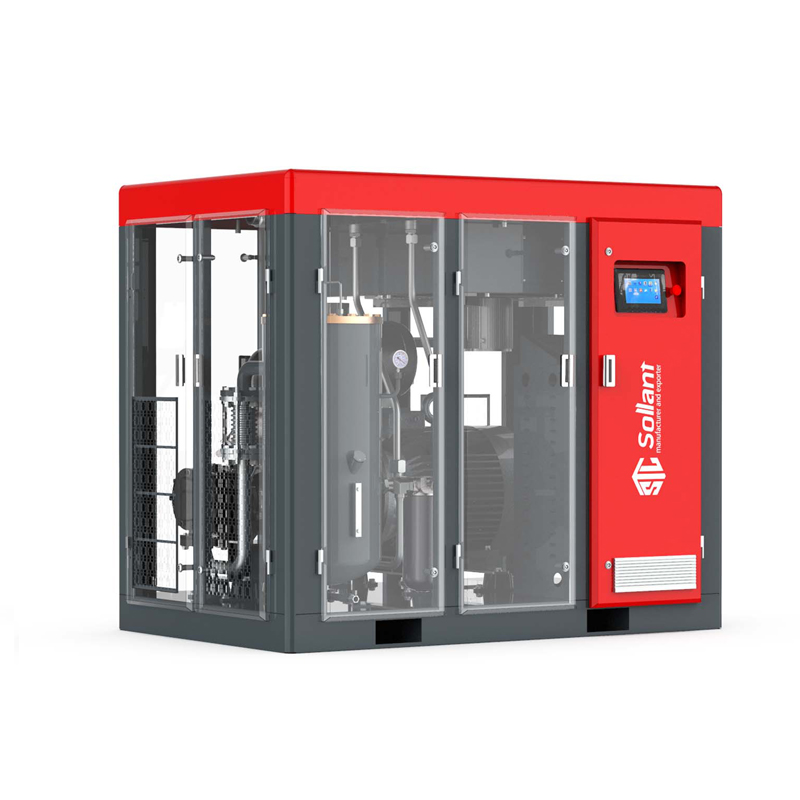

As an important form of energy generation, the rotary screw air compressor is widely used in all aspects of life and production. Sollant rotary screw air compressor is durable and its appearance is made of high-quality cold-rolled steel plate cover. It adopts a spray molding process and high temperature baking at 250 ° C. It is corrosion-resistant and durable for a long time.

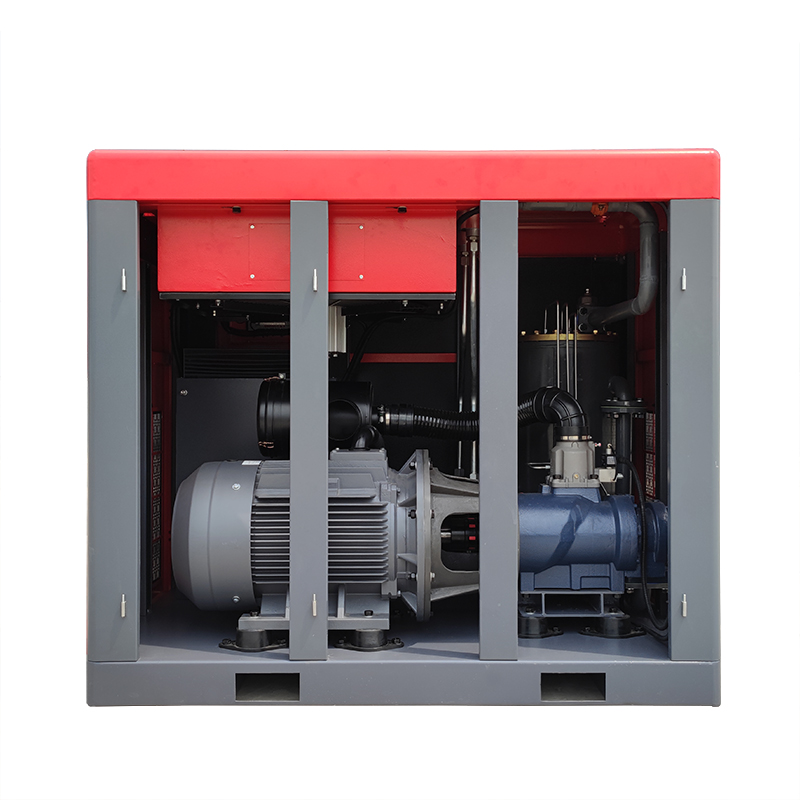

The rotary screw air compressor components of the electrical appliance are the components of the world-famous brand Schneider Electric/ABB, with silver contacts, the service life is more than 3 million times, and the safe use is guaranteed for a long time. The bearings are imported from Switzerland, which better improves the use efficiency of the host machine, reduces wear and helps increase the smoothness of the meshing.

Leading Rotary Screw Air Compressor Manufacturer

Develop Your Business with Sollant

Rotary Screw Air Compressor

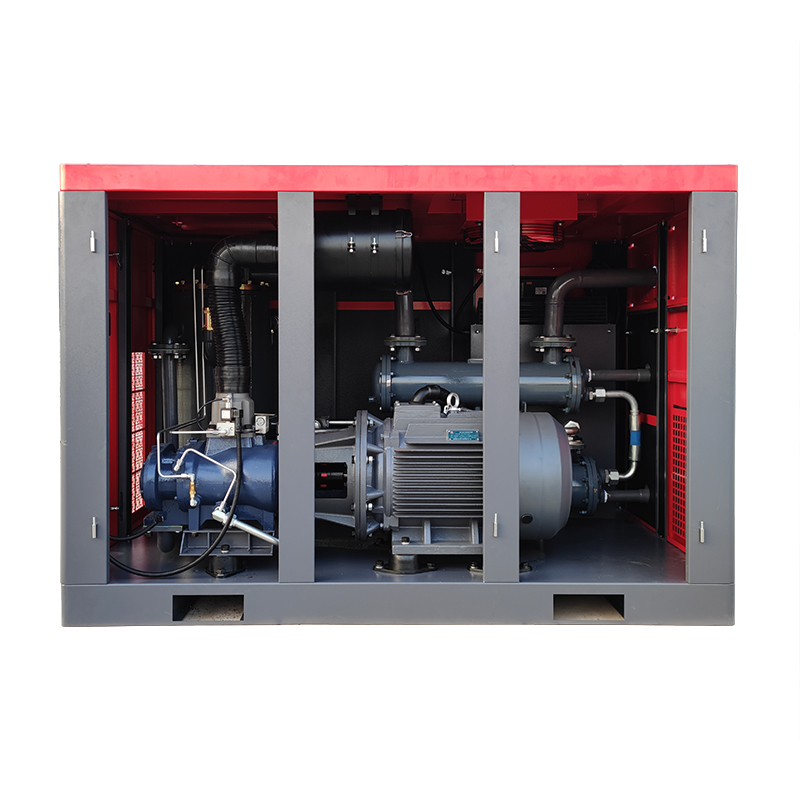

A rotary screw air compressor is a type of gas compressor, such as an air compressor, that uses a rotary-type positive-displacement mechanism. The gas compression process of a rotary screw is a continuous sweeping motion, so there is very little pulsation or surging of flow, as occurs with piston compressors.

Rotary screw air compressors operate by trapping air between two meshed rotors and reducing the volume of that trapped air as it moves down through the rotors. This reduction in volume results in compressed air, which can then be used to power air tools, inflate tires, or in numerous other applications.

Why Choose Sollant

Rotary Screw Air

Compressor?

Sollant rotary screw air compressor,has unique design concept and better quality assurance.

- Its system has the design advantage of small size.

- Low cost but high quality with long service life.

- They are easier to maintain and repair.

- Lower noise of rotary screw air compressor operation.

- Few parts, easy assembly for clients.

- Sollant’s rotary screw air compressor does not leak oil.

Keep us Update on Latest Air Compressor Newsletter

Choosing the Right Rotary Screw Air Compressor for Your Business

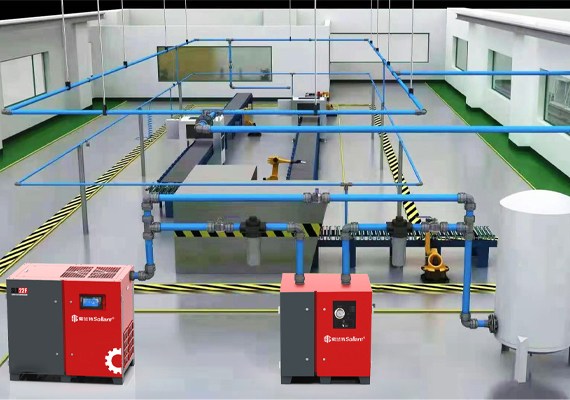

In today’s competitive industrial landscape, the efficiency and reliability of equipment play a pivotal role in determining the success of business operations. Among the array of equipment utilized, air compressors hold a critical position, providing the essential power source for a multitude of applications across industries. At the heart of this power generation lies the rotary screw air compressor, a versatile and efficient machine that has become a cornerstone of modern industrial processes.

The selection of the right air compressor is not merely a technical decision; it’s a strategic choice that impacts productivity, energy efficiency, and overall operational costs. The efficiency gains and enhanced performance achieved through proper air compressor selection can significantly influence a business’s bottom line.

Among the various types of air compressors available, the rotary screw air compressor stands out for its robustness, efficiency, and adaptability. These compressors are widely employed in industrial applications ranging from manufacturing and construction to automotive and electronics, serving as the powerhouses that drive pneumatic tools, machines, and processes.

Understanding Your Business Needs

In the pursuit of choosing the optimal rotary screw air compressor, a fundamental step is to thoroughly understand the specific requirements of your business. This involves a comprehensive assessment of various factors that influence the selection process.

- Assessing Compressed Air Requirements

Begin by delving into the nature of your applications and the extent to which they rely on compressed air. Evaluate the types of tools, machinery, or processes that will be powered by the compressor. Assess the required pressure levels, airflow rates (measured in cubic feet per minute or CFM), and any fluctuations in demand that may occur.

- Special Considerations for Unique Environments

Beyond the basic operational requirements, delve into any special considerations unique to your business environment. Evaluate noise levels; if your operations occur in noise-sensitive areas, selecting a low-noise rotary screw compressor may be crucial. Consider space constraints, particularly if your available space is limited. Additionally, factor in any environmental considerations, such as regulations governing emissions or the need for oil-free air in certain applications.

- Capacity Alignment with Growth Projections

A significant aspect of selecting the right rotary screw air compressor is ensuring its capacity aligns with your business’s growth projections. Investing in a compressor that meets your current needs is essential, but equally important is its ability to accommodate future expansion. A compressor that can easily scale to handle increased demand without straining its capabilities ensures a smooth transition as your business grows.

By meticulously evaluating these aspects, you’ll gain a clearer understanding of your business’s unique requirements, setting the stage for a more informed decision when it comes to selecting the appropriate rotary screw air compressor.

Types of Rotary Screw Air Compressors

As you delve deeper into the process of selecting the ideal rotary screw air compressor for your business, it’s crucial to consider the different types available and how they align with your specific operational requirements.

- Fixed-Speed and Variable-Speed Rotary Screw Compressors

Two primary categories of rotary screw air compressors are fixed-speed and variable-speed compressors. Fixed-speed compressors operate at a constant speed, while variable-speed compressors can adjust their speed to match the compressed air demand. Each type has its distinct advantages and considerations.

- Energy Efficiency and Operational Flexibility

Discuss the energy efficiency and operational flexibility offered by both fixed-speed and variable-speed compressors. Fixed-speed compressors tend to be more straightforward and cost-effective upfront, making them suitable for applications with relatively stable air demand. On the other hand, variable-speed compressors shine in energy efficiency by adjusting their speed to match the fluctuating air demand, resulting in significant energy savings over time.

- Suitability for Specific Business Needs

Provide insights into scenarios where each type may be more suitable based on specific business needs. For instance, businesses with consistent and predictable air demand may find fixed-speed compressors to be an efficient choice. In contrast, variable-speed compressors are well-suited for operations with varying air demand patterns, ensuring energy savings during periods of lower demand.

Additionally, discuss how the choice between fixed-speed and variable-speed compressors impacts factors such as maintenance requirements, lifespan, and overall cost of ownership.

By comprehensively understanding the differences between these types and how they align with your operational requirements, you can make an informed choice that optimally supports your business’s goals and needs.

Compressor Size and Capacity

Selecting the right size and capacity for your rotary screw air compressor is a critical step that directly impacts its performance and efficiency. A well-sized compressor ensures that your business’s compressed air needs are met while optimizing energy consumption and operational costs.

The Concept of Compressor Sizing

Delve into the concept of compressor sizing and its importance in achieving optimal performance. Proper sizing involves matching the compressor’s capacity to your specific air demand, preventing underutilization or overexertion. Sizing impacts the compressor’s ability to deliver the required air pressure and flow rates consistently.

Understanding Air Pressure and Air Flow Requirements

Explain the significance of air pressure (measured in pounds per square inch or PSI) and air flow (measured in cubic feet per minute or CFM) requirements. Highlight how different applications demand varying pressure levels and airflow rates, and how these factors are interdependent.

Calculating Required Compressor Size

Offer guidance on how to calculate the required compressor size based on the identified air demand. Discuss the formulas and considerations involved in determining the appropriate CFM and PSI ratings for your compressor. Encourage businesses to consider both current and future air demand to ensure the chosen compressor can accommodate growth.

Provide examples and scenarios to illustrate how accurate sizing contributes to enhanced compressor efficiency, reduced energy consumption, and prolonged equipment lifespan.

By thoroughly understanding compressor sizing and accurately assessing your business’s air demand, you’ll be equipped to make a choice that optimizes performance and efficiency while aligning with your operational goals.

Energy Efficiency and Cost Considerations

Energy efficiency is not only a critical environmental concern but also a substantial factor in determining the overall cost-effectiveness of your rotary screw air compressor. Understanding the relationship between energy consumption and operational costs is essential in making an informed decision.

Discuss the significance of energy consumption in contributing to operational costs. Explain how a compressor’s energy usage directly affects electricity bills, which can constitute a significant portion of a business’s expenditures. Emphasize the importance of selecting an energy-efficient compressor to mitigate this financial impact.

Highlight the role of energy-efficient features such as variable-speed drives (VSD) and advanced control systems. Explain how VSD allows compressors to adjust their speed according to air demand, leading to optimal energy consumption. Additionally, discuss how advanced control systems optimize compressor operation, further enhancing energy efficiency.

Explore the long-term cost savings associated with investing in an energy-efficient rotary screw air compressor. Illustrate how reduced energy consumption translates into lower monthly bills, providing businesses with tangible financial benefits over the compressor’s lifespan. Discuss how these savings accumulate over time, making an energy-efficient investment an economical choice.

Use real-world examples or case studies to demonstrate how businesses have achieved substantial cost reductions by prioritizing energy efficiency when selecting their rotary screw air compressors.

By emphasizing the connection between energy efficiency and long-term cost savings, businesses can make a strategic choice that aligns with their financial objectives and sustainability goals.

Noise Levels and Environmental Factors

Beyond performance and efficiency, factors such as noise levels and environmental considerations play a crucial role in selecting the right rotary screw air compressor for your business. Addressing these factors ensures not only a conducive work environment but also a responsible approach to sustainability.

Start by discussing the importance of considering noise levels, particularly in indoor or noise-sensitive environments. Explain how excessive noise can lead to employee discomfort, hinder communication, and even result in compliance issues with noise regulations. Emphasize the significance of creating a comfortable and productive workplace through prudent compressor selection.

Discuss the advantages of opting for low-noise rotary screw compressors. These compressors are designed to minimize noise emissions while maintaining high levels of performance. Explore how their quieter operation contributes to a more harmonious work environment, enhancing both employee satisfaction and overall productivity.

Touch on the environmental impact of rotary screw compressors and their different types. Briefly explain the benefits of oil-free and oil-injected compressors in terms of environmental responsibility. Discuss how oil-free compressors eliminate the risk of oil contamination in the air supply, making them ideal for applications that demand pristine air quality. Contrast this with oil-injected compressors that require careful maintenance to prevent oil-related environmental concerns.

Use examples or case studies to illustrate how businesses have successfully addressed noise concerns and aligned with environmentally conscious practices by selecting the right rotary screw compressor type.

By considering noise levels and environmental factors, businesses can create a conducive work environment while contributing to responsible and sustainable operations.

Quality and Reliability

Selecting a high-quality and reliable rotary screw air compressor is essential to ensure smooth operations and minimize downtime. In this section, delve into the factors that contribute to the quality and reliability of a compressor, guiding businesses in making a well-informed choice.

- Reputable and Reliable Manufacturer

Start by emphasizing the significance of choosing a reputable and reliable compressor manufacturer. Discuss how a manufacturer’s track record and reputation directly impact the quality of their products. Highlight the importance of partnering with manufacturers known for their commitment to engineering excellence and customer satisfaction.

- After-Sales Support and Service

Highlight the role of warranties, service contracts, and after-sales support in ensuring trouble-free operation. Explain how comprehensive warranties and service contracts provide businesses with peace of mind, knowing that any potential issues will be promptly addressed by the manufacturer. Discuss the value of reliable after-sales support in maintaining the longevity and performance of the compressor.

- Gathering Information about Manufacturer Reputation

Explore ways to gather information about the manufacturer’s reputation and customer reviews. Discuss the importance of researching online reviews, testimonials, and references from other businesses that have used the manufacturer’s products. Encourage businesses to reach out to the manufacturer directly to inquire about their manufacturing processes, quality control measures, and customer support.

Installation and Maintenance

Installing and maintaining your rotary screw air compressor correctly is essential for ensuring optimal performance, efficiency, and longevity. In this section, focus on the crucial aspects of installation and ongoing maintenance.

Begin by discussing the importance of proper installation by trained professionals. Explain how the correct installation ensures that the compressor operates at its intended efficiency and performance levels. Highlight the risks of improper installation, such as decreased efficiency, increased wear and tear, and even safety hazards. Encourage businesses to rely on certified technicians for installation.

Offer insights into the significance of regular maintenance routines for preserving the compressor’s longevity. Discuss how routine maintenance, including filter replacements, lubrication, and component inspections, can prevent breakdowns, extend the compressor’s lifespan, and maintain its efficiency. Explain how neglecting maintenance can lead to costly repairs and reduced operational efficiency.

Highlight the role of maintenance contracts and scheduling in ensuring consistent and effective compressor upkeep. Explain how maintenance contracts provide businesses with a structured approach to servicing their compressors, reducing the risk of oversight. Discuss the benefits of regular maintenance scheduling in preventing unexpected downtime and optimizing operational reliability.

Provide practical advice on how to set up maintenance routines, collaborate with technicians, and establish maintenance contracts to keep your rotary screw air compressor operating efficiently.

Sollant Rotary Screw Air Compressor Factory in Turkey: Pioneering Excellence

In the world of rotary screw air compressors, one name that shines brightly is Sollant. As a dedicated Turkish manufacturer with a state-of-the-art factory, Sollant has established itself as a leading supplier of high-quality rotary screw air compressors.

Sollant stands as a beacon of innovation and expertise in the field of air compression technology. Nestled within the dynamic landscape of Turkey, Sollant’s rotary screw air compressor factory represents the culmination of years of dedication to quality and performance. With a customer-centric approach, Sollant has carved a niche for itself as a trusted partner for industries seeking reliable and efficient air compression solutions.

At the heart of Sollant’s success lies its advanced rotary screw air compressor factory. This state-of-the-art facility is equipped with cutting-edge machinery, precision engineering tools, and a team of skilled professionals who share a passion for excellence. From design to manufacturing, every step in the production process is meticulously executed to ensure that Sollant’s rotary screw air compressors exceed industry standards.

Sollant’s factory is a hub of expertise and innovation. The company’s commitment to research and development fuels a constant drive to enhance the efficiency, performance, and reliability of its rotary screw air compressors. This dedication to staying ahead of the technological curve ensures that customers receive products that are not only of the highest quality but also equipped with the latest advancements in air compression technology.

Quality is the cornerstone of Sollant’s factory operations. Each rotary screw air compressor that leaves the factory undergoes stringent quality assurance tests, ensuring that it meets Sollant’s rigorous standards for performance and durability. This unwavering dedication to quality translates into compressors that offer unparalleled reliability, reduced maintenance requirements, and long-term customer satisfaction.

As industries continue to evolve, Sollant’s rotary screw air compressor factory remains at the forefront of innovation, quality, and customer satisfaction. With a world-class facility, a dedicated team, and a commitment to excellence, Sollant stands as a true industry leader in the Turkish market. Businesses seeking reliable, efficient, and customized rotary screw air compressors need look no further than Sollant’s factory operations, where pioneering excellence is the driving force behind every compressor that bears the Sollant name.