Diesel Portable Air Compressor Manufacturer

Sollant diesel mobile air compressors are designed to get the job done for days on end. Designed to cover almost all applications, from construction and infrastructure to landscaping, oil and gas, factory backup air, and more.

All of our compressors are manufactured with reliability, durability, and performance in mind. Flexibility for greater utilization, easy maintenance, simple interface, multiple engine options, and more

SOLLANT Energy-Saving Two-Stage Mobile Compressor, as the leader of energy-saving mobile screw air compressors in China, is committed to providing customers with more economical, efficient and energy-saving mobile air compressors.

We provide high-level products and services for global oil and gas extraction, pipeline construction, mine drilling and blasting, water well drilling, sand mining and dredging, infrastructure construction and other fields. Sollant mobile machine adopts energy-saving two-stage spindle with high compression efficiency, a powerful brand motor, an efficient cooling system, stable and reliable control system, and its performance is even better!

Smarter and more human

- Microcomputer control, soft start.

- Fault warning, motor high-temperature protection

- Beautiful and elegant

More efficient and energy-saving

- Two-stage energy-saving air end

- Strong brand momentum

More stable and reliable

- High-temperature performance test,

- Durable and reliable,

- Multiple air ducts for air intake,

- Adapt to various working conditions.

More environmentally friendly and more convenient

- Low noise and low vibration

- More convenient and longer life of consumables.

Energy-efficient product design concept

Carefully designed for customers to achieve better energy-saving results, saving up to 30% of fuel!

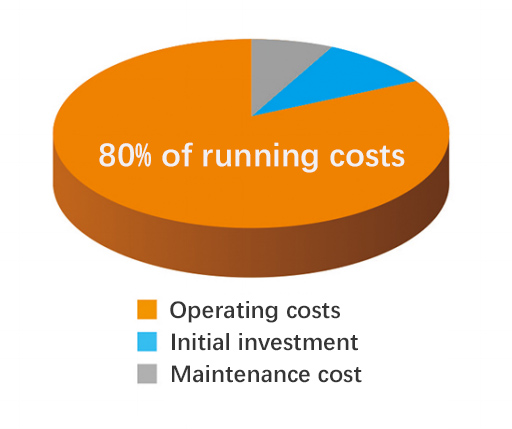

Application strategy for compressor products: Reduce operating costs!!!

During the entire life cycle of a diesel mobile screw compressor, operating costs account for up to 80% of the total cost. Reducing the fuel cost during the operation of a diesel mobile screw compressor plays a decisive role in reducing the overall cost of the machine's life cycle. Therefore, reducing product operating costs has become an increasingly important focus for users.

Diesel engines

Diesel engines

The entire series meets the National Stage III emission standards, with reliable quality, strong power, stable operation, and convenient maintenance.

Two-stage screw air end

■Large rotor, low speed

■ Low-pressure ratio, high efficiency

■Energy saving and reliable

Intake valve

Integrating anti-return, proportional adjustment, and other functions into one, no wearing parts, more energy-saving and reliable

Heat sink

It adopts a side-entry structure, which makes installation and maintenance more convenient. The aluminum plate-fin type increases the heat exchange area with the air, effectively improving the cooling effect.

Microcomputer controller

Button operation, large screen display, concise and clear, accurately detects and displays diesel engine speed, oil pressure, water temperature, fuel tank level, exhaust pressure, temperature, etc., and has automatic alarm and shutdown functions.

High-pressure filter

High-pressure filter

■Large flow rate, small size, automatic drainage is more convenient

■Effectively filter the condensed water in the control pipeline, making the control more efficient and sensitive

Flexible coupling

■High elasticity, strong ability to absorb shock and vibration

■Compact structure, easy installation and maintenance-free

■During axial transmission, it has good radial and angular compensation capabilities.

Oil and gas tank

Oil and gas tank

Adopt optimal flow rate and structural design, small oil content, and easy maintenance

Air filter

Air filter

Equipped with a safety filter element to more effectively protect the host and engine in dusty environments

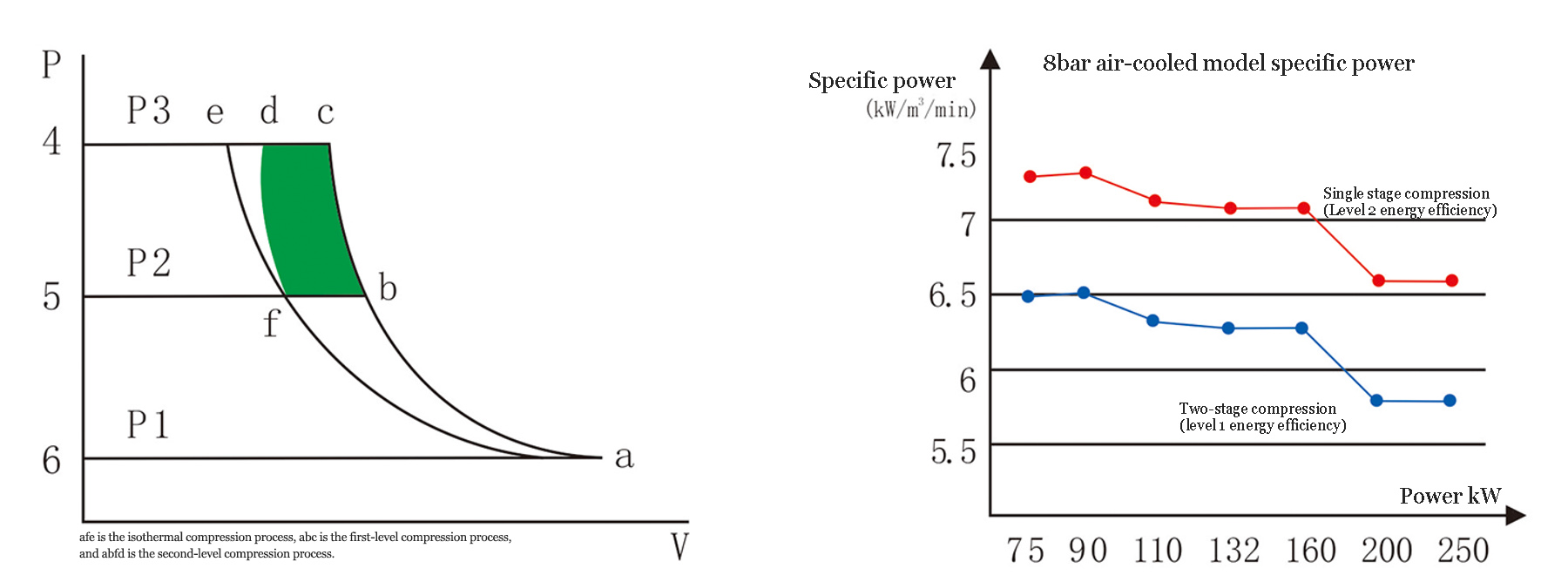

◆The operating temperature is lower than that of single-stage compression, and it tends to be more power-saving isothermal compression, with a theoretical energy saving of 8%.

◆The compression ratio of each stage is lower, the internal leakage is reduced, and the volumetric efficiency is increased by 5~10%.

◆It is helpful to adjust the rotor of each stage to achieve the optimal linear speed range of 25~35m/s, and obtain the highest compression transmission efficiency.

Keep us Update on Latest Air Compressor Newsletter

Fueling Productivity Anywhere: Benefits of Portable Diesel Screw Compressors

In the bustling world of modern industries, where efficiency and mobility reign supreme, the demand for reliable and accessible compressed air has never been more critical. At the heart of meeting this demand lies the concept of portable diesel screw compressors—a technological innovation that has redefined the way businesses approach their operations.

In a landscape where productivity hinges on seamless processes and uninterrupted workflows, these versatile devices have emerged as indispensable tools.

The essence of reliable and on-demand compressed air cannot be understated. It forms the lifeblood of a multitude of industries, from construction and mining to agriculture and emergency services. Whether it’s powering pneumatic tools on a remote job site or supporting critical operations during emergencies, the availability of compressed air can spell the difference between success and setbacks.

It is within this context that we delve into the focal point of this article: the advantages of portable diesel screw compressors and their transformative role in elevating productivity across diverse operational environments.

As we journey through the realms of industrial efficiency and mobility, we will explore the myriad benefits that portable diesel screw compressors offer. From their ability to provide a consistent and on-demand air supply to their unmatched versatility in applications, we will uncover how these devices have revolutionized the way industries approach their tasks. With a spotlight on their role in delivering productivity across different settings, we embark on a comprehensive exploration of the advantages that make portable diesel screw compressors a cornerstone of modern operations.

The Power of Portability

In the dynamic landscape of industrial operations, the concept of portability has emerged as a game-changing factor that influences productivity, efficiency, and adaptability. The ability to swiftly move essential equipment to where it’s needed holds immense significance, especially in environments where traditional infrastructural support might be limited. This is where portable diesel screw compressors step into the spotlight, offering a solution that bridges the gap between accessibility and necessity.

Consider scenarios where compressed air plays a pivotal role: a construction site in a remote location, a mining operation deep within a rugged terrain, or even emergency response situations in areas lacking consistent power sources. In these settings, the need for a reliable and mobile source of compressed air becomes paramount.

Traditional fixed compressor installations may be impractical or even unfeasible due to logistical constraints or the urgency of the task at hand. It’s in such challenging scenarios that the significance of portability becomes apparent.

Enter the portable diesel screw compressor—a marvel of engineering that not only embodies the concept of mobility but also delivers the critical compressed air supply that industries rely on. These compact powerhouses can be transported with ease to virtually any location, ensuring that the required air supply is available exactly where it’s needed most.

Whether it’s powering pneumatic tools on a construction site nestled in the mountains or delivering the essential air pressure for rescue operations in remote areas, portable diesel screw compressors offer a versatile solution that caters to the demands of various industries.

In the subsequent sections of this article, we will delve deeper into the applications of portable diesel screw compressors and the scenarios where their portability shines. From construction projects that require flexible on-site operations to emergency services that need dependable air supply in crisis situations, the power of portability is a driving force behind the transformative role these compressors play in modern industrial settings.

Versatility in Applications

The versatility of portable diesel screw compressors extends across a wide spectrum of industries and applications, making them invaluable assets in diverse operational scenarios. From powering tools on construction sites to enabling critical operations in remote areas, these compressors have found their niche in a plethora of fields, each reaping the benefits of their mobile and reliable air supply.

- Construction Sites:

Portable diesel screw compressors have become a staple on construction sites, where their mobility addresses the dynamic nature of these projects. They power pneumatic tools, such as jackhammers and nail guns, ensuring seamless operations without the limitations imposed by fixed installations. By eliminating the need for air hoses tethered to a central location, these compressors enhance worker mobility and overall efficiency. This mobility is especially crucial on larger construction sites where multiple tasks are underway simultaneously, and access to compressed air can make or break project timelines.

- Mining Operations:

In the rugged terrains of mining operations, where space is often at a premium and infrastructure may be limited, portable diesel screw compressors play a vital role. These compressors provide a dependable air supply for various applications, including drilling, rock blasting, and ventilation systems. The ability to relocate the air supply to different work areas in mines ensures optimized operations, enabling mining companies to extract resources efficiently and safely.

- Agriculture:

In the agricultural sector, portable diesel screw compressors find utility in a range of tasks. From inflating tires and powering pneumatic machinery to maintaining grain storage facilities, these compressors contribute to the overall efficiency of agricultural operations. On expansive farmlands, where access to compressed air might be sporadic, these compressors provide a reliable solution to address pressing tasks promptly, ultimately aiding in increased productivity.

- Emergency Services:

During emergency response situations, such as natural disasters or accidents, portable diesel screw compressors prove to be invaluable assets. They facilitate operations by providing air supply for rescue tools, equipment inflation, and medical devices. In situations where power sources may be disrupted, these compressors operate autonomously, enabling first responders to fulfill their critical duties without being hindered by external limitations.

The adaptability of portable diesel screw compressors is perhaps best demonstrated by their widespread adoption across such diverse applications. Their impact is seen not only in the enhanced efficiency and productivity of operations but also in the potential lives saved during emergencies.

As we proceed through this exploration, we will uncover specific instances where these compressors have become indispensable tools in various industries, substantiating their role in revolutionizing the way work is accomplished in a myriad of settings.

On-Demand Air Supply

In the dynamic landscape of modern industries, where efficiency is paramount and delays can lead to substantial losses, the availability of on-demand compressed air stands as a critical factor. Compressed air serves as a backbone for a plethora of tasks, from powering tools to maintaining equipment functionality.

In various work environments, the ability to access compressed air quickly and reliably can make the difference between smooth operations and costly downtime.

Portable diesel screw compressors play a pivotal role in addressing the need for an on-demand air supply. Unlike fixed installations, which might require routing air hoses across considerable distances, these compressors provide a compact and self-contained solution. Equipped with efficient diesel engines, they can swiftly be deployed to any location, ensuring a consistent and reliable source of compressed air.

Consider a scenario in a construction site where workers are utilizing pneumatic tools to carry out tasks. Without a readily available air supply, operations might come to a grinding halt as workers wait for the air supply to be established.

Portable diesel screw compressors eliminate this waiting time, providing an immediate source of compressed air. The ability to have a self-contained air supply allows operations to continue seamlessly, contributing to heightened productivity and minimized downtime.

In numerous industries, downtime is a significant concern, as it leads to reduced productivity and increased costs. Portable diesel screw compressors prove their worth by preventing such downtime and delays.

For instance, on a mining site, a sudden equipment breakdown might require immediate maintenance. The availability of a portable compressor ensures that tools used for maintenance, such as pneumatic wrenches, are always powered, allowing repairs to be carried out swiftly without waiting for an external air supply to be established.

The agile nature of portable diesel screw compressors ensures that industries can respond to changing demands and unexpected situations with efficiency. By guaranteeing a consistent and reliable source of compressed air, these compressors stand as a proactive solution that prevents interruptions and maintains a seamless workflow.

Independent Power Source

In many operational settings, especially those located in remote or off-grid areas, access to reliable electricity can be a significant challenge. Industries operating in such environments require equipment that can function autonomously, regardless of the availability of power. This is where the advantage of diesel-powered compressors becomes evident, offering a robust solution that ensures continuous operation even in areas with unreliable or non-existent electrical infrastructure.

Portable diesel screw compressors provide a unique autonomy that is highly sought after in industries requiring on-demand compressed air. Unlike electrically powered compressors that rely on a stable grid connection, diesel-powered compressors carry their power source with them. This autonomy grants industries the flexibility to operate in remote or challenging locations, where setting up traditional power sources might be impractical or financially unviable.

Consider a construction site deep in the heart of a forest or a mining operation in a desolate terrain. These locations might lack reliable access to electrical power. In such scenarios, portable diesel screw compressors become invaluable allies.

Their self-contained diesel engines allow them to operate independently, ensuring a continuous supply of compressed air even in the absence of external power sources. This autonomy empowers industries to undertake projects in locations that were previously considered inaccessible or unsuitable for operation due to power constraints.

One of the most remarkable features of portable diesel screw compressors is their ability to operate without relying on external power sources. This attribute not only enhances their versatility but also ensures the seamless continuation of operations during power outages or in areas where electrical infrastructure is scarce.

Whether it’s emergency services responding to a crisis or construction crews working in remote areas, the independence provided by diesel-powered compressors is a crucial factor that eliminates reliance on external factors beyond one’s control.

As we delve further into the advantages of portable diesel screw compressors, the self-reliance and autonomy they offer will continue to stand out. Their capacity to operate in a self-sustained manner, regardless of the surrounding conditions, underscores their capability to adapt to various operational challenges.

Energy Efficiency and Cost Savings

- Energy Efficiency of Diesel Engines and Cost Savings

In the pursuit of operational excellence, industries are continually seeking ways to optimize energy consumption and reduce costs. One of the inherent advantages of portable diesel screw compressors lies in their energy efficiency, driven by the utilization of diesel engines.

Diesel engines have long been celebrated for their superior fuel efficiency compared to their gasoline counterparts. This energy efficiency translates into tangible cost savings for businesses operating in a variety of industries.

- Optimized Fuel Consumption for Consistent Performance

Portable diesel screw compressors exemplify this energy efficiency by optimizing fuel consumption while delivering consistent performance. These compressors are engineered to strike a balance between power output and fuel usage, ensuring that each drop of fuel contributes to maintaining a reliable air supply.

The efficiency of diesel engines, coupled with the precision design of screw compressors, results in a streamlined conversion of fuel into compressed air. This optimization not only guarantees consistent performance but also extends the operational duration of the compressor per fuel tank, maximizing productivity while minimizing fuel expenditure.

- Economic Benefits of Reduced Operational Costs

Reduced operational costs stand as a significant economic benefit of utilizing portable diesel screw compressors. With their energy-efficient diesel engines and optimized fuel consumption, these compressors contribute to lowering overall operational expenditures.

For industries that heavily rely on compressed air, such as construction, mining, and agriculture, the cumulative effect of reduced fuel usage can lead to substantial cost savings over time. Businesses can redirect these saved resources to other critical areas, reinvest in operations, or enhance their bottom line.

Consider a construction company using pneumatic tools powered by a portable diesel screw compressor. The efficient fuel consumption of the compressor means that the company spends less on fuel to power their tools, ultimately translating into more favorable project economics.

Similarly, in emergency response scenarios, where quick and continuous access to compressed air is crucial, the cost-effectiveness of diesel-powered compressors ensures that first responders can operate efficiently without worrying about excessive fuel consumption.

Streamlined Maintenance

- Maintenance Advantages of Portable Diesel Screw Compressors

In the realm of industrial equipment, efficient maintenance practices are pivotal in ensuring seamless operations and minimizing costly downtime. Portable diesel screw compressors stand out not only for their mobility and performance but also for their maintenance advantages that contribute to optimized operations and extended equipment lifespan.

- Minimizing Maintenance Requirements and Downtime

Modern designs of portable diesel screw compressors are engineered to minimize maintenance requirements and downtime. Compared to their older counterparts, these compressors boast advanced technologies and engineering innovations that optimize their operation and reduce the need for frequent maintenance interventions. This is a particularly significant advantage in industries where operational continuity is paramount.

With their self-contained diesel engines and streamlined design, portable diesel screw compressors eliminate the complexities associated with traditional compressors, such as belt adjustments and lubrication schedules. These advancements translate to reduced maintenance frequency, enabling businesses to focus on their core operations without being burdened by excessive maintenance routines.

- Easy Access to Components and User-Friendly Interfaces

An essential aspect of streamlined maintenance is the ease of access to critical components and user-friendly interfaces. Portable diesel screw compressors feature designs that prioritize quick and straightforward maintenance procedures. Components that require regular inspection or servicing are strategically placed for easy access, minimizing the time required for routine checks or replacements.

Moreover, user-friendly interfaces and diagnostics systems allow operators to monitor the compressor’s health and performance effortlessly. These systems often provide real-time data on operating conditions, oil levels, and maintenance schedules, enabling proactive maintenance planning and swift responses to any anomalies.

Consider a scenario where a construction crew is utilizing a portable diesel screw compressor on a remote project site. The ease of maintenance means that the crew can quickly perform routine checks and preventive measures, ensuring the compressor remains in optimal condition. This agility in maintenance contributes to sustained efficiency and productivity, even in challenging work environments.

Sollant Diesel Mobile Screw Air Compressors: Empowering Industries with Mobility and Performance

In the dynamic landscape of modern industries, the demand for reliable and efficient compressed air solutions has never been more critical. As businesses strive for operational excellence and productivity, the role of high-quality air compressors becomes paramount.

In this pursuit, Sollant, a leading player in the air compressor industry, stands out as a beacon of excellence. With a commitment to innovation, performance, and mobility, Sollant has emerged as a professional and reputable supplier of air compressors, particularly renowned for its expertise in diesel mobile screw air compressors.

At the heart of Sollant’s success lies its unwavering dedication to providing advanced air compressor solutions to a diverse range of industries. In Turkey, Sollant has positioned itself as a prominent supplier of top-tier air compressors, with a focus on diesel mobile screw compressors. Leveraging its years of experience and technical expertise, Sollant has carved a niche for itself by offering a comprehensive range of products designed to meet the unique needs of its clients.

Sollant’s specialization in diesel mobile screw air compressors underscores its commitment to delivering excellence in both mobility and performance. These compressors are meticulously engineered to offer seamless mobility to industries operating in various settings, from construction sites to mining operations and emergency response scenarios. The mobility of Sollant’s diesel mobile screw compressors enables businesses to access reliable compressed air precisely where it’s needed, eliminating the constraints imposed by fixed installations.

Sollant’s reputation for excellence extends beyond mobility, as its diesel mobile screw compressors are engineered to deliver unparalleled performance. With advanced designs and cutting-edge technology, these compressors provide a consistent and reliable supply of compressed air, enhancing operational efficiency across industries. Whether it’s powering tools, enabling critical operations, or supporting emergency response efforts, Sollant’s compressors exemplify the fusion of reliability and performance.

Sollant understands that different industries have distinct requirements when it comes to air compressors. With this in mind, the company offers industry-centric solutions tailored to the specific needs of its clients. From construction companies seeking portable air supply solutions to mining operations in challenging terrains, Sollant’s diesel mobile screw compressors cater to a wide spectrum of industries, contributing to heightened productivity and operational agility.

In the realm of air compressors, Sollant has emerged as a trailblazer, consistently delivering quality, mobility, and performance to industries worldwide. Its expertise in diesel mobile screw compressors showcases a profound understanding of the demands of modern businesses, where efficiency, reliability, and adaptability are paramount. As industries continue to evolve and seek innovative solutions, Sollant remains steadfast in its commitment to shaping the future of air compressor technology and contributing to the success of its clients across the globe.